Why Steel Wheel

The modern steel wheel: an alternative to aluminum wheels to address safety, financial and environmental concerns

Mahdi sadeghi moghaddam

CEO, WHEELMOLD.co, Mashhad, Iran

CEO@wheelmold.com

Abstract

Although aluminum rims are popular, they come with safety and environmental concerns and can be expensive, especially with rising global aluminum prices. There is not enough research and information about the impact of the increase in the global price of aluminum on the price of aluminum rims, as well as their environmental and safety consequences in accidents. The purpose of this article is to raise awareness among consumers and rim manufacturers about these issues and to suggest strategies for safe, cost-effective, environmentally friendly, and visually appealing alternatives. Finally, it highlights the advantages of steel rims made of modern steel with high strength as a solution.

1. Introduction

The invention of the wheel around 3500 BCE in Mesopotamia (modern-day Middle East ) has had a profound impact on human history, significantly influencing transportation, technology, and societies. Today, the wheel is an indispensable component in transportation, with individuals spending a considerable amount of time driving each year. Car rims, a key element of wheels, are crucial for three primary reasons: safety, functionality, and aesthetic considerations.

In the matter of safety, if there is a malfunction in the car's engine, gearbox, etc., the driver can still stop the car. However, if the car's wheel fails, it can lead to a catastrophic event, as the car itself may stop the driver's life forever!

On the other hand, the wheel rim is a vital functional part of a car, supporting the vehicle's weight, transmitting the engine's driving force to the road through the tires, and playing a crucial role in movement, braking, control, and steering. However, it is susceptible to significant stress from static loads and impacts, making it prone to damage.

In respect to aesthetically, the wheels are the soul of the car and one of the first things that people notice. Experts in car design consider the wheel rim to be one of the two main elements of a car's beauty. The wrong design of the wheel rim can ruin the car's overall appearance, while changing the rim can give an old car a new, modern, and attractive look.

Alloy wheels and steel wheels represent the primary wheel types utilized in modern-day vehicles. Alloy wheels crafted from cast aluminum alloy are favored for their visual attractiveness, lightweight design, and performance advantages. Nonetheless, they face three primary challenges: impact safety, elevated expenses, and substantial energy usage during manufacturing. These issues are expected to gain significance as global aluminum prices rise in the future and the target of achieving zero carbon emissions by 2050 approaches (Shekhar et al, 2020).

Steel wheels are manufactured through roll forming and pressing steel sheets, followed by assembly. They are recognized for their Inexpensive, durability and strength against road impacts, making them a safe and cost-effective choice for all types of roads and weather conditions. Also, the production of steel rims consumes much less energy than aluminum rims and is therefore more environmentally friendly. However, traditional steel rims have drawbacks such as heavy weight and limited diversity in appearance. These issues can be mitigated by using high-strength steel, geometric shapes, and new processes to create modern steel rims that are lighter and more stylish. Modern steel wheels are designed to make cars safer, more affordable, fuel-efficient, stylish, and environmentally responsible (Kumar and Devaki Devi, 2019)

Given the issues with aluminum rims that have been discussed without adequate research or solutions, this article is a focused attempt to offer a remedy. It highlights the advantages of contemporary steel rims compared to aluminum rims in the present and future automotive wheel market, benefiting both consumers and steel rim producers.

2. Modern steel wheels: an alternative to aluminum wheels to address safety, financial and environmental concerns

The resurgence of steel in the automotive industry is attributed to the development of better steel and better wheels. New steel options include microalloy HSLA, dual-phase, and bainitic steels, which are high-strength and advanced high-strength steels (DeCicco, 2005). These steels have significantly improved the design of styled steel wheels. Notably, these designs feature large ventilation openings, known as High Ventilation Area (HVA), which mimic the thin-spoke appearance of some aluminum alloy wheels. The progress in steel industry technology, combined with new sheet metal forming processes like hot stamping, has enabled the manufacturing of steel wheels that are not only economical, lighter, and safer than aluminum wheels, but also more eco-friendly throughout their lifespan.

As a result, modern steel rims offer the advantages of aluminum rims at a reduced cost and with minimal environmental impact, in addition to the inherent benefits of steel (see Figure 1).

Figure 1. moden steel wheel; a comnination of the advantages of ally wheel and steel wheel

Wheel manufacturers agree that simulation software has greatly improved during the last few years, allowing for far more precise designs. Improved CAD/CAM data has resulted in improved wheel uniformity and dimensional precision.

Although the consumption of modern steel rims with a stylish design has increased greatly, eight reasons can be predicted for the sharp increase in the consumption of modern steel rims in the future.

- 2.1 Significant rise in aluminum prices in the upcoming decades

- 2.2 Eco-Friendliness

- 2.3 Safety as the priority

- 2.4 Fantastic fresh design

- 2.5 Increased Profit

- 2.6 Reduced warranty expenses

- 2.7 light weight

- 2.8 Consumer choice

- 2.1 Significant rise in aluminum prices in the upcoming decades

Alloy wheels made of aluminum alloy are favored for their visual appeal, lightweight design, and performance benefits. As explained in the introduction , they face three main challenges: impact safety and maintaining vehicle safety, high price, and significant energy consumption during production. The last two issues have become more important with the increase in the global price of aluminum and the imperative to reduce carbon emissions.

The 2030s have been dubbed the 'Decade of Aluminum' due to increased global demand. Currently, we use two analytical approaches, technical and fundamental, which predict an increase in the price of aluminum and support investment opportunities in steel wheels (Karthik et al., 2016).

- 2.1.1 Aluminium Fundamental price analysis:

- Demand Growth: Used in everything from buildings, solar panels, automobiles and aeroplanes, beverage cans, aluminium is often a proxy for industrial activit . The aluminum sector is anticipated to undergo substantial expansion in the near future, driven by decreased fuel usage, the uptake of lighter materials, and a drive for net-zero emissions in industries like automotive, aerospace, construction, and electronics.

- Supply Constraints: Factors such as limited bauxite reserves, energy costs, and environmental regulations could constrain the supply of aluminum, leading to upward pressure on prices.

- Economic Growth: The overall economic growth trajectory, particularly in emerging markets, can impact demand for aluminum and consequently affect its price.

- Geopolitical Factors: Trade policies, sanctions, and geopolitical tensions in major aluminum-producing regions can disrupt supply chains and influence prices.

- Aluminum as a substitute metal: Commodity analysts at major global banks predict a robust decade for copper demand due to diminishing reserves, limited new discoveries, and challenges faced by Chile. The surge in demand could reach up to 900%, with prices potentially increasing by up to 100%, leading to a greater demand for aluminum as a more cost-effective substitute metal, especially in the electrical sector (Wang et al, 2011)

- 2.1.2 AluminiumTechnical price analysis:

We will proceed to scrutinize the long-term technical super cycle charts for all commodities, followed by a specific emphasis on the aluminum chart in conjunction with the copper chart.

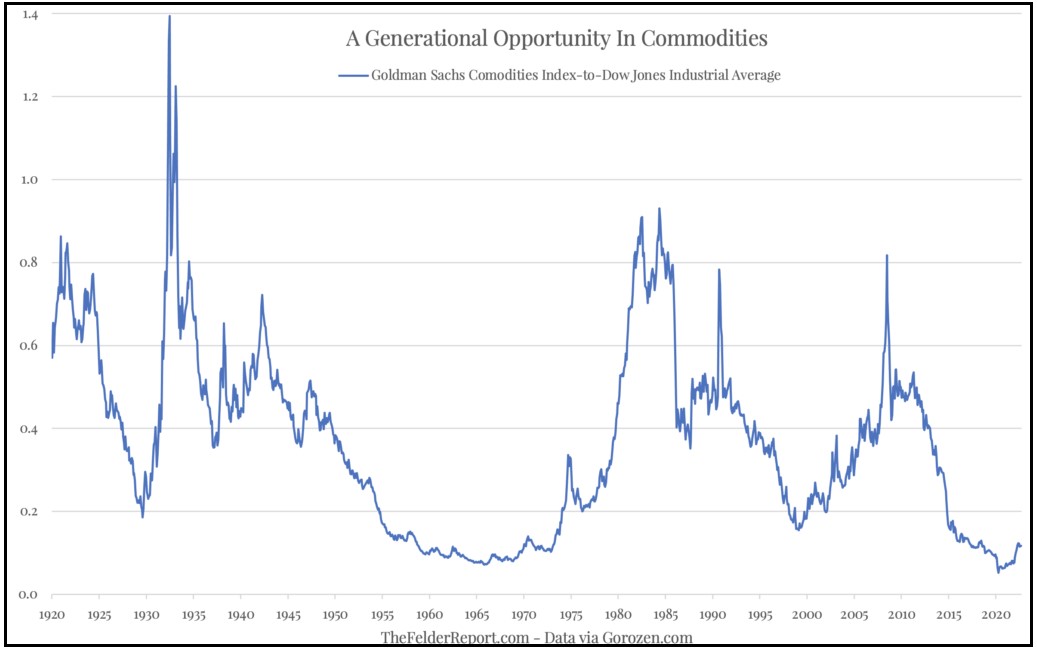

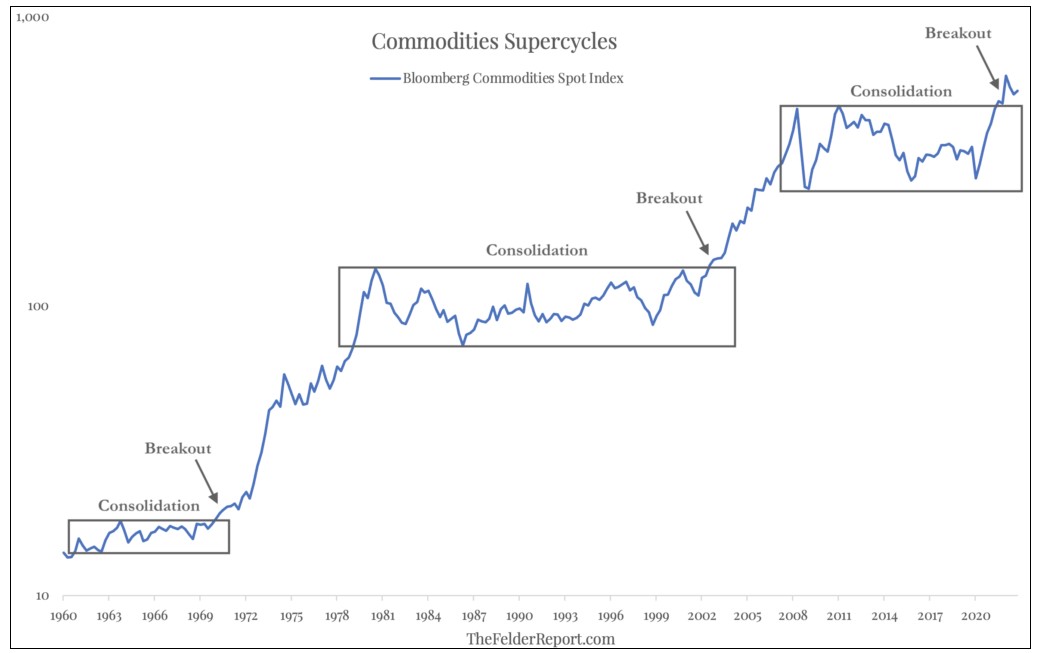

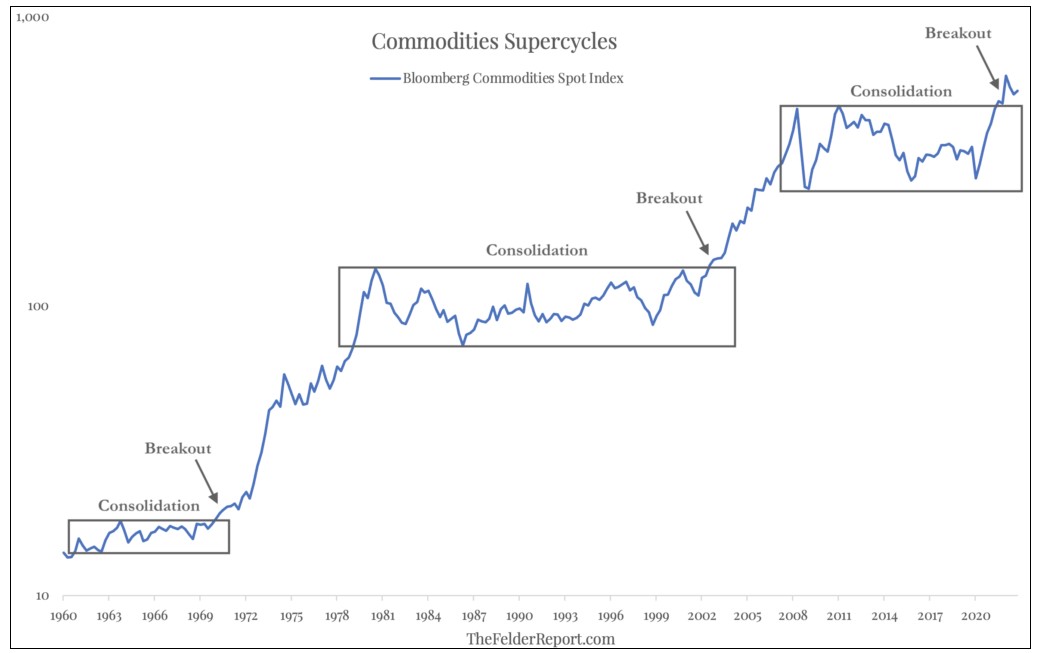

Several technical indicators indicate a long-lasting and stable positive upward trend in global commodity prices. The concurrent examination of the hypercycle charts of two significant commodity indices, including the 100-year Goldman Sachs index(Figure 2), and the 60-year Bloomberg index(Figure 3), reveals the onset of this upward trend globally. This trend in commodity prices is anticipated to persist for at least the next two decades.

Figure 2. the 100-year Goldman Sachs index

Figure 3. the 60-year Bloomberg index

As Paul Tudor Jones once said, “When you get a range expansion, the market is sending you a very loud, clear signal that the market is getting ready to move in the direction of that expansion,” and the history of previous breakouts in the index confirms this analysis. This assessment is in line with the International Energy Agency's projection of significant price hikes in commodities over the next two decades, fueled by a strong global drive towards sustainable energy and infrastructure developments aimed at achieving net carbon neutrality by 2050. This transition is expected to result in a substantial increase in demand for industrial metals, especially non-ferrous metals like aluminum and copper.

Figure 4.copper and aluminum super cycle chart

A graph depicting the prices of aluminum and copper highlights a connection between these metals influenced by demand substitution (Figure 4). The chart shows that the price trend for both metals has increased by approximately 100% every two decades. Moreover, the hyper-cycle graph forecasts a substantial rise in the prices of all commodities in the next two decades. Nevertheless, the anticipated surge in demand for copper and aluminum over the next two decades is expected to lead to a more significant price increase for these metals compared to other commodities.

- 2.2 Eco-Friendliness of Steel Compared to Aluminum : sTEEL WHEELS CUT CO2

The World Health Organization reports that 7 million individuals perish annually due to air pollution, with cars, especially vehicles, being a significant contributor to this figure. Greenhouse gas emissions from aluminum production exceed steel production by at least four times (Schwarz, 2004). Therefore, utilizing high-strength steel that meets weight reduction standards can greatly benefit the environment by curbing air pollution. Modern steel wheels offer unique environmental advantages over aluminum wheels, thanks to the incorporation of HSLA steel, their lighter weight, increased durability, affordability, and elevated safety standards. These features make styled steel wheels an appealing option for those seeking to decrease greenhouse gas emissions and endorse sustainable practices. As per Duning from Maxion Wheels company, steel wheel production is approximately six times more energy-efficient than aluminum, emphasizing the importance of considering steel wheels in the industry to genuinely reduce CO2 emissions (Zheng et al, 2015)

- 2.3 Safety is the priority

The World Health Organization's 2018 data showed 1.35 million traffic fatalities annually, emphasizing the importance of car safety (WHO, 2018) The wheel, particularly the wheel rim, is crucial for vehicle performance and reducing accidents. Aluminum rims have lower impact endurance and are more likely to fracture, causing detachment from the wheel upon breakage, which can result in brake system failure and potential car overturning, posing severe safety risks (Figure 5).

Figure 5. alloy wheels being more prone to breaking

In contrast, steel rims are highly durable and resistant to road impacts, remaining intact and attached to the wheel after collisions, thereby supporting the wheel tire and brake system efficiently. This impact resistance makes steel rims safer in accidents compared to aluminum rims (Figure 6). However, traditional steel rims are heavier and lack visual appeal. These issues can be addressed by employing high-strength steel, innovative designs, and cutting-edge manufacturing techniques to create modern steel rims that are lighter and more stylish. Furthermore, the wheel disc's optimized blade structure, featuring an expansive ventilation area, improves heat dissipation, reduces brake temperatures, and elevates brake performance and safety. Consequently, modern steel wheels contribute to vehicle safety through impact resistance and enhanced braking system performance (Wang and Zhang, 2010)

Figure 6. steel rims being more resistant to road impacts

- 2.4 Fantastic fresh design

Consumers can now enjoy the styles they like with all the benefits of steel.styled steel wheels can include fixed hubcaps and decorative bands or completely attached wheel covers. They can be highly appreciated and visually appealing elements for automobile package choices, such as trendy spoked steel wheel designs with built-in trimmings(Figure 7).

|

Figure 7. appealing frame and looks of modern steel wheels |

Anillustration of these wheels is the ventilated steel wheel, characterized by a structurally sound frame with extensive spaces reminiscent of spokes, accentuated further by complementary fixed trimmings. Attractively, this configuration provides considerable cost savings compared to cast aluminum alternatives (Ballo et al, 2018)

Figure 8. Multiplicity of design from one wheel

According to wheel manufacturers, steel wheels have improved in strength, weight, size, and the ability to accept a wide variety of integrated trim designs. This, along with the concept of a low-cost steel base wheel applied to many platforms, is making it difficult to justify aluminum wheels for many applications (Figure 8).

- 2.5 Increase producer profits

Modern steel rims boost manufacturers' profit margins and offer cost savings to consumers and automakers. Given that the cost of steel raw materials is approximately a quarter of aluminum, and the production process for steel rims - involving pressing, roll forming, assembly, and finishing - is significantly cheaper than that of aluminum rims, which includes die casting, heat treatment, machining, and finishing, the modern steel rim's cost is substantially lower than that of an aluminum rim. Despite this cost advantage, modern steel rims maintain a similar appearance to aluminum rims while offering superior strength and environmental benefits. This cost efficiency can result in profit margins of up to 100% for steel rim manufacturers per wheel. Simultaneously, it remains a cost-effective choice for consumers, potentially saving them and automakers up to 50% compared to alloy rims and reducing warranty expenses.

- 2.6 Reduced warranty expenses

According to the Wheels Task Force of AISI, there is a notable difference in warranty costs between steel and aluminum wheels, which varies depending on the company and model. The number of warranty incidents per thousand vehicles for aluminum ranges from four to 30, while for steel, it is only one per thousand. This results in a warranty cost savings of 15 to 50 times for steel. Therefore, utilizing high-strength steel wheels can lead to significant savings in warranty repairs.

- 2.7 light weight

By employing advanced high-strength steels like DP600 or microalloy steel, and advanced sheet metal forming techniques such as hot stamping, it is possible to produce steel wheels that are up to 20% lighter than aluminum wheels. This technological advancement allows for the creation of steel wheels that are not only lighter than aluminum but also more environmentally sustainable throughout their entire lifespan. For instance, in the case of the Chevy Malibu, the steel wheel weighs less than the aluminum wheel. Specifically, the larger 16" steel wheel is comparable in weight to the smaller 15" aluminum wheel (Grubisic and Fischer, 1984)

- 2.8 Consumer choice

An investigation, financed by AISI and executed by a reputable market research institution, demonstrated that swapping standard aluminum wheels with stylized steel wheels in upgrade bundles might preserve option bundle interest and income. The survey centered around customer inclinations regarding styled wheels in autos and SUVs, revealing that customers view styled steel wheels as more powerful and safe when contrasted with aluminum equivalents. Moreover, the examination uncovered that clients regard steel wheels as of higher worth, prepared to spend more on them, and rate them equivalent or superior to wheels produced using different materials. Another exploration directed by a broadly perceived advertising research association involving almost 2,700 members likewise displayed solid favoritism toward styled steel wheels, with buyers expressing confidence in steel's strength and security over aluminum.

3. Conclusion

Current research highlights the growing significance of modern steel wheels as a viable alternative to aluminum wheels in addressing safety, financial, and environmental concerns. It emphasizes the potential of steel wheels to offer cost-effectiveness, safety, stability, light weight construction, performance, and durability compared to aluminum. New steel options include microalloy HSLA, dual-phase, and bainitic steels, which are high-strength and advanced high-strength steels, have significantly improved the design of new steel wheels, have enhanced aesthetics and reduced weight, promoting energy efficiency. The shift towards steel wheels is driven by their superior benefits over aluminum, especially amidst projected increases in aluminum prices in future and the environmental advantages of steel . In conclusion, it should be noted that investing in the production of modern steel rims has great potential for future profitability due to the increase in demand and the lower cost of production. Additionally, increasing the production of modern steel rims in the automobile industry, besides increasing the profits of producers, will directly help to enhance the safety of human lives and protect the environment.

References

F. Ballo, R. Frizzi, G. Mastinu, D. Mastroberti, G. Previati, C. Sorlini, Lightweight Design and Construction of Aluminum Wheels, in: SAE Technical Papers, SAE International, 2016. https://doi.org/10.4271/2016-01-1575.

J.M. DeCicco. "Steel and iron technologies for automotive lightweighting", Environ. Defense, March. 3 (2005)

V. Grubisic, G. Fischer, Procedure for optimal lightweight design and durability testing of wheels, Int. J. Veh. Des. 5 (1984) 659–671.

B.V.V. Kumar, K. Devaki Devi, "Design Analysis and Optimization of a Wheel Rim", The International Journal of analytical and experimental modal analysis, ISSN NO: 0886-9367, Volume XI, Issue IX, September/2019.

A.S. Karthik, et al. "Static Analysis of Alloy Wheel using FEA." International Journal for Innovative Research in Science & Technology (IJIRST) 12 (2016).

H.G. Schwarz, "Aluminum Production and Energy". Encyclopedia of Energy, 81–95. https://doi.org/10.1016/ B0-12-176480-X/00372-7

C. Shekhar, B. lakshmipati Rao, V. Krishna, "Design and structural analysis of car alloy wheel using with various materials", international journal of advance scientific research and engineering trends, ISSN (Online) 2456-0774, Volume 5, Issue 7, July 2020.

Venkateswarlu, Gudise, and M. Sharma. "Design and Analysis of Alloy Wheel with Different Alloys." International Journal of Advance Research in Science and Engineering 6.10 (2017): 2488-2495.

L. Wang, Y. Chen, C. Wang, Q. Wang, "Fatigue life analysis of aluminum wheels by simulation of rotary fatigue test", Strojniski. Vestnik/J. Mech. Eng. 57 (2011) 31–39, https://doi.org/10.5545/sv-jme.2009.046

X. Wang, X. Zhang, "Simulation of dynamic cornering fatigue test of a steel passenger car wheel", Int. J. Fatigue. 32 (2010) 434–442, https://doi.org/10.1016/j.ijfatigue.2009.09.006.

WHO (2018) "Global status report on road safety". Issue: 17 June 2018 https://www.who.int/publications-detail-redirect/9789241565684

Z. Zheng, S. Yuan, T. Sun, S. Pan, "Fractographic study of fatigue cracks in a steel car wheel", Eng. Fail. Anal. 47 (2015) 199–207, https://doi.org/10.1016/j.engfailanal.2014.09.010

تعداد 0 دیدگاه به ثبت رسیده است