capability wheel tools

Tooling for Wheel Manufacturing

MED Precision Tools Company is dedicated to crafting steel wheel's producing tools. With a full range of design and manufacturing capabilities, including machining, testing, and debugging centers, we are equipped to fulfill large orders according to customer specifications. For further inquiries or interest, please don't hesitate to reach out to us.

The tooling required for steel wheel production comprises three key components: dies for producing spokes, discs, and wheel rim production tools, along with assembly and customized tools. Explore our array of specific dies and tools to find the ideal solutions for your steel wheel manufacturing needs.

- Tooling for Wheel disk Manufacturing

- Automatic Stamping Line Series (Transfer Production)

The demand for passenger car wheels now emphasizes qualities like light weight, high strength, and appealing aesthetics. Steel wheels made from high strength plates are increasingly popular. To meet the need for efficient production, manufacturers require standardized production methods and durable dies for wheel disc production lines. MED, a specialist in wheel production tooling, has designed tools and dies specifically for manufacturing high strength plate wheel spokes and discs on automated stamping lines. Depending on the shape of the steel wheel disc and the capabilities of the manufacturer, this procedure involves 6 to 8 mold stages for profiling, punching, and deformation of the wheel disc.

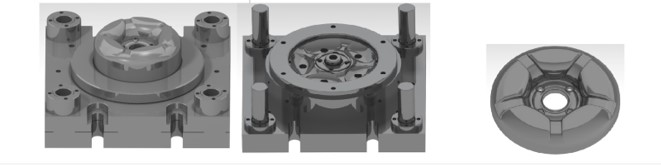

OP1) Blanking-punching forming Compound Die

3D Drawing Samples

OP2) Forming and punching Die

3D Drawing Samples

OP3) Trimming Die

3D Drawing Samples

OP4) Flanging and forming Die

3D Drawing Samples

OP5) Vent Hole&Bolt hole Piercing Compound Die

3D Drawing Samples

OP6) Bolt Hole Deburring Tool

3D Drawing Sample

- Independent Series tooling : ( manual dies)

To cater to the demands of Independent Series tooling for wheel disc production lines, we prioritize precise process and die structure design. Generally, the manufacturing of traditional wheel discs involves nine distinct processes: blanking-punching, preliminary drawing, profiling, trimming and punching, flanging, screw hole punching, screw hole deburring, air hole punching, and air hole deburring. Each of these processes necessitates a dedicated die. At MED, armed with our experience and knowledge, we streamline these nine stages into four or five stages, tailored to our customers' facilities, which can decrease the production cost of the product, subsequently lowering the final price of the steel rim product, and boosting the profit margin. We are devoted to enhancing our customers' profitability.

Op1 ) Blanking-punching forming Compound Die

Op2) Forming Die

Op3) Flanging & Screw and center hole punching Compound die

Op4) Air hole punching die

- Tooling for Wheel Rim Manufacturing

Rim tools utilized in specialized wheel production lines

- Marking tools

Mounted on a coiling machine to imprint wheel production details while coiling is in progress.

- Flaring Die

Following vacuum thermal treatment, the flaring die's core undergoes NC precision machining to guarantee both hardenability and dimensional precision.

- Roll Forming Die

The roll forming die, essential for crafting tubeless wheel rims, can be constructed as a single unit or with a split design to facilitate simpler adjustments and maintenance.

The tools used in the production of wheel rims is composed of Cr12MoV and various other materials. Through a vacuum thermal treatment following rough machining, it achieves a hardness exceeding HRC60. Subsequent NC precision machining post-quenching guarantees precise sizing and smooth surface finish.

- Expanding Tool

Passenger cars

Work range:

width: 2.5-8inch

diameter: 12-17.5inch

- Valve hole punching tools

The valve hole punching tool is mounted on the press, where it carries out the process of punching valve holes in the rim.

MED Precision Tools Company is dedicated to crafting steel wheel's producing tools. With a full range of design and manufacturing capabilities, including machining, testing, and debugging centers, we are equipped to fulfill large orders according to customer specifications. For further inquiries or interest, please don't hesitate to reach out to us.

تعداد 0 دیدگاه به ثبت رسیده است